Struggling with unstable tariffs1 and supply chain delays2? Your ceramic sourcing feels riskier than ever. We found a way to get stability without losing the speed your brand needs.

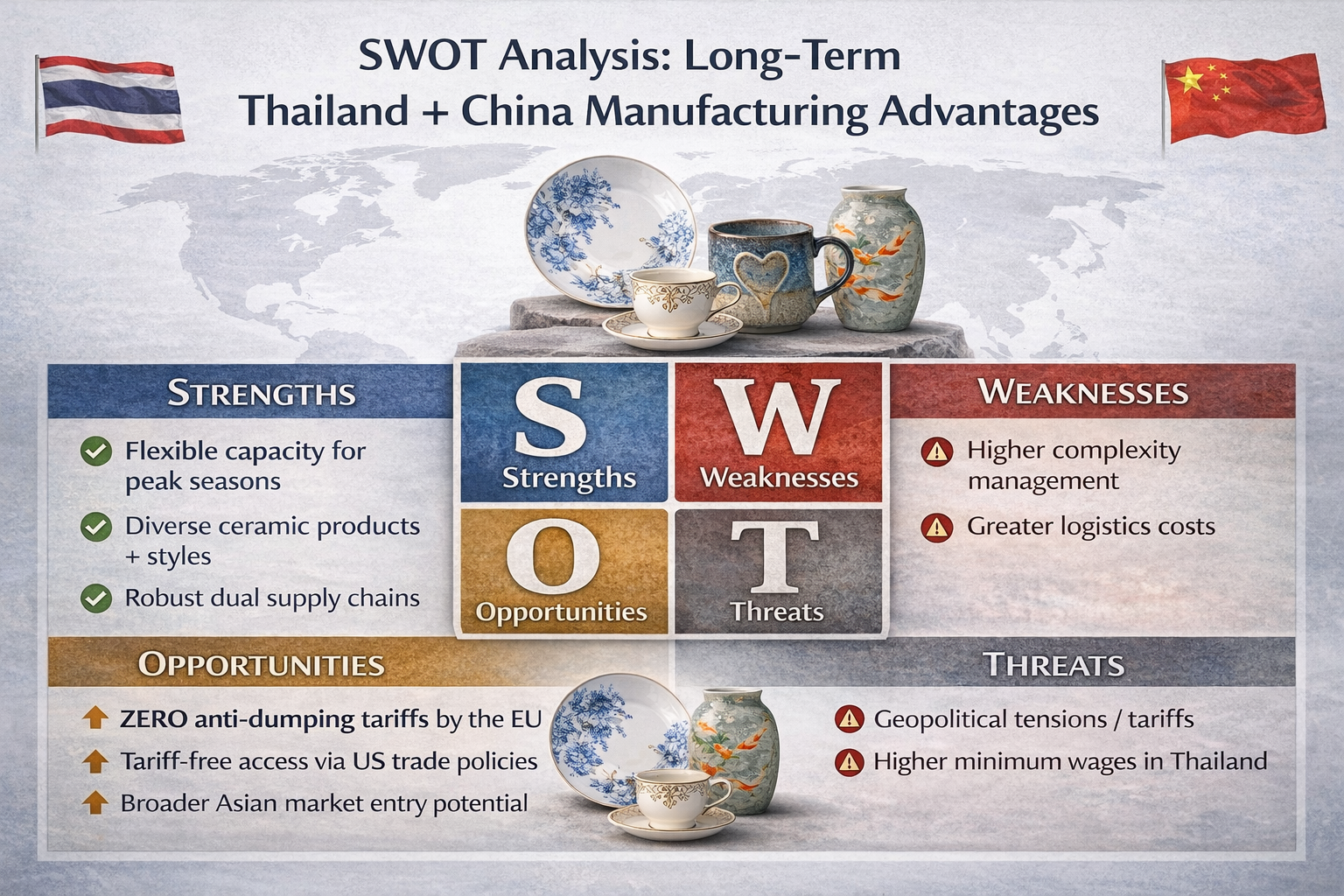

The best choice is not China or Thailand; it is using both. China offers unmatched speed and technical skill for development. Thailand provides tariff stability3 for US and EU markets. A dual-country strategy4 gives you flexibility, reduces risk, and ensures consistent production for your brand.

Making sourcing decisions used to be much simpler. We focused almost entirely on finding the lowest cost. Today, that approach is a recipe for disaster. The world has changed, and our sourcing strategies must change with it. It is no longer about one country, but about building a resilient supply chain5 that can handle uncertainty. This is how we keep your brand moving forward, no matter what happens next.

Why Is Ceramic Manufacturing No Longer a Single-Country Decision?

Worried that trade wars could suddenly halt your production line? Relying on a single country for manufacturing is a huge gamble today. There is a much safer way to source your ceramics.

Sourcing is no longer a single-country decision because of tariffs, anti-dumping duties6, and global uncertainty7. Diversifying your manufacturing base between countries like China and Thailand protects your business from sudden policy changes, prevents cost spikes, and reduces long-term supply chain risks.

The game has completely changed for sourcing managers. A few years ago, the main question was about cost. Now, the main question is about risk. Tariffs, like the Section 301 duties8 in the US, can add a huge percentage to your costs overnight. Anti-dumping duties in Europe can make a product line unprofitable. This uncertainty makes it impossible to plan. We saw this firsthand with clients who were suddenly facing massive, unexpected bills. Relying on one country puts your entire supply chain at the mercy of politics and trade disputes. It creates a single point of failure. What happens if that country has a major lockdown? Or a new trade policy is enacted? Your production stops. Your customers are left waiting. That is why we decided we could not depend on just one location. We had to build a more flexible system to protect our partners.

| Risk Factor | Single-Country Sourcing (e.g., China only) | Dual-Country Sourcing (China + Thailand) |

|---|---|---|

| Tariff Changes | High Impact. A new tariff can halt profitability. | Low Impact. Production can shift to the unaffected country. |

| Production Delays | High Risk. Lockdowns or holidays stop everything. | Lower Risk. One location can potentially back up the other. |

| Cost Volatility | High. Costs can spike due to duties or currency shifts. | Moderate. You can choose the most cost-effective location. |

| Flexibility | Low. You are locked into one system and its limits. | High. You get the best of both worlds: speed and stability. |

What Makes China Still Critical in Ceramic Manufacturing?

Do you have a complex design that requires perfect execution and a fast turnaround? You might think you have to compromise on quality to get speed. But you do not have to.

China is still unmatched for development speed, technical depth9, and handling complex processes. Its mature supply chain10 and manufacturing DNA mean faster sampling, intricate decoration, and efficient scaling, especially for projects that demand high levels of skill and precision.

China's role in ceramic manufacturing is not just about volume anymore. It is about speed and skill. We run our own in-house development center in China, and the difference is clear. When a New York-based client needs a sample for a complex item, they need it fast. The Chinese manufacturing ecosystem is built for this. The raw material suppliers, the mold makers, and the decoration experts are all part of a deeply integrated network. This allows us to turn a design into a physical sample in record time. For difficult techniques like multi-color decals, electroplating, or precise gold tipping, the level of expertise is simply deeper. This manufacturing "DNA" means that even on complex projects, the process is efficient and predictable. When a project involves intricate details or requires a large production run after a quick development phase, China is often the most logical and effective choice.

Why Are Buyers Increasingly Looking at Thailand for Production?

Are you worried that new anti-dumping duties6 or tariffs could suddenly erase your profit margins? You need a stable production base for your core product lines. Thailand offers that stability.

Buyers are looking to Thailand for its tariff stability3, especially for the US market. It also offers a 0% anti-dumping duty11 for ceramics going to Europe. This makes Thailand an ideal and predictable location for long-term, repeatable production programs where cost stability is critical.

Stability is the new currency in global sourcing. While China offers incredible speed, Thailand offers predictability, which is just as valuable. For our partners selling into the United States and Europe, this is a game-changer. The unstable tariff situation with China12 means costs can change unexpectedly. By moving production of established, high-volume items to our facility in Thailand, we can lock in costs. There are no surprise Section 301 tariffs for US-bound goods. For our European partners, the 0% anti-dumping duty11 on Thai ceramics is a huge advantage. This allows brands to plan their pricing and inventory for seasons to come without fearing that a policy change will ruin their business. We invested in our own mold-making capabilities in Thailand to ensure that the quality and precision we establish during development in China can be perfectly replicated for mass production. This makes Thailand the workhorse for long-term, stable supply.

How Do Buyers Decide Which Country Is Right for Each Project?

You have a new ceramic project, but you are not sure where to produce it. Is it a China project or a Thailand project? The decision depends on more than just the final price.

The right country depends on your target market, product complexity, required speed, and order volume. Fast, complex development often starts in China. Stable, high-volume orders for the US or EU are better suited for Thailand. The goal is to match the project to the right strengths.

Choosing the right production location is a strategic decision. Cost is a factor, but it is not the only one. I always walk my clients through a few key questions to find the best fit. First, where are you selling the product? If the primary market is the US or Europe, we have to seriously consider Thailand to avoid tariffs and duties. Second, how complex is the design? If it involves very intricate decals, multiple glazes, or difficult hand-painting, China's deep technical expertise gives us an edge, especially during development. Third, how fast do you need it? For a rush job or a quick market test, China's integrated supply chain is almost always faster. Finally, what is the volume? A small test order of 300 pieces might be best for China, while a 10,000-piece repeat order is a perfect fit for Thailand's stable production lines. It is not about one country being "better," but about using them intelligently.

| Factor | Best Choice: China | Best Choice: Thailand |

|---|---|---|

| Target Market | Global markets without punitive tariffs | USA & Europe |

| Complexity | High (e.g., complex decals, gold trim) | Medium to Low (e.g., simple shapes, solid colors) |

| Speed | Very Fast (rapid development & sampling) | Moderate (steady, planned production) |

| Volume | Flexible (small test runs or large orders) | Best for long-term, repeat orders |

Why Does a Dual-Country Setup Reduce Sourcing Risk?

What would you do if your only factory shut down for a month unexpectedly? A dual-country manufacturing setup acts as an insurance policy. It gives you options when you need them most.

Having operations in both China and Thailand provides critical flexibility. It protects buyers from being derailed by regional lockdowns, policy changes, or capacity issues. If one country faces a problem, we have a strategic alternative to keep production moving, ensuring supply chain resilience13.

Risk management is now a core part of my job. A dual-country setup is our single best tool for it. I remember during a recent lockdown, a client had an urgent order stuck. Because we have our Thai facility, we were able to quickly move a portion of their production there to keep their business running. This is the flexibility that protects our partners. It is not just about big disasters, either. Sometimes a factory in one country is simply at full capacity. Instead of telling a client they have to wait two months, we can check our production schedule in the other country. This structure insulates our partners from shocks. A sudden tariff hike in China? We can plan to move the next production run to Thailand. A port strike in Thailand? We have the option to ship from China. You are no longer vulnerable to the fate of a single location.

Why Do Complex Ceramic Projects Often Fail with a Single Factory?

Have you ever had a project that required multiple complex techniques, only to have the final product look inconsistent? This happens because most factories specialize. They cannot be experts at everything.

Most factories excel at one type of clay (like porcelain or stoneware) or one process (like hand-painting). A single complex project needing multiple skills often fails because one factory rarely has the expertise to handle all requirements well, leading to quality issues.

I have seen this happen too many times. A brand designs a beautiful collection. It includes a porcelain dinner plate with a decal, a stoneware mug with a reactive glaze, and a semi-porcelain vase that is hand-painted. They give the entire project to one large factory. The result? The porcelain plates are perfect, but the stoneware mugs have glaze defects, and the hand-painting on the vase is sloppy. This is because the factory’s real strength was in high-fire porcelain and decal application. They were not experts in stoneware or artisanal painting. No single factory can be the best at everything. They specialize to be efficient. One is great with stoneware, another with fine porcelain. One has the best decal team, while another has skilled painters. Trying to force one factory to do it all leads to compromises and, often, failure.

How Does a Trading-Led Model Simplify Multi-Country Manufacturing?

How do you manage production across different factories and countries without hiring a huge team? You work with a partner who does the complex coordination for you, giving you a single point of contact.

A trading-led model14 simplifies everything by providing one expert point of contact. We handle the complex task of factory matching, quality control, and logistics across multiple locations. This is more effective than relying on one factory and supports lower, more flexible MOQs for our partners.

My clients are busy. They are brand managers and procurement experts, not factory floor supervisors. They do not have time to manage five different suppliers across two countries. Our model is designed to solve this. We act as their single point of contact. They tell us what they need, and we handle the rest. We take their project and match each component to the right factory in our network. The porcelain plate goes to our porcelain specialist in China. The stoneware mug goes to our stoneware partner. We manage the quality control at each location, ensuring everything is consistent. Because we work with a network of specialized factories, we can be much more flexible with Minimum Order Quantities (MOQ)15. A single giant factory needs large orders to be efficient. We can place smaller orders with specialized factories, which is perfect for brands wanting to test new products with a 300-500 piece run.

How Does This Strategy Support Long-Term Buyers, Not Just One Order?

Are you looking for a low price on your first order, or a reliable partner for the next five years? For professional buyers, consistency and stability are far more valuable than a one-time discount.

This strategy supports long-term buyers by prioritizing consistency over initial pricing. A dual-country model allows brands to scale production without switching suppliers, providing the stability that sourcing managers value more than short-term savings. We build partnerships, not just process orders.

The best client relationships I have are built on trust and stability, not on chasing the lowest possible price on a single order. Sourcing managers for established brands know that consistency is key. They need to know that the blue on their mug will be the same shade a year from now. They need to know that their products will arrive on time, every time. Our dual-country strategy4 is built for this. A brand can start with a small, complex test order in China. As the product proves successful, we can scale production and move it to Thailand for long-term, tariff-stable supply. The brand gets to scale without the risk and headache of finding and vetting a whole new supplier. This long-term view is why sourcing managers stick with us. They know we are thinking about how to protect their business and support their growth for years to come.

Conclusion

The real question is not "China or Thailand?" The right question is "How do I build a flexible sourcing strategy to stay in control?" Future-ready ceramic sourcing requires both deep technical skill and a smart location strategy.

Looking to reduce risk while maintaining speed and quality in ceramic manufacturing? Start with the right production strategy.

Understanding current tariffs can help you navigate and mitigate risks in your ceramic sourcing strategy. ↩

Learn how to manage and overcome supply chain delays to keep your production on track. ↩

Discover how tariff stability can protect your business from sudden cost spikes and policy changes. ↩

Explore how a dual-country strategy can provide flexibility and reduce risks in your supply chain. ↩

Learn strategies to create a supply chain that can withstand global uncertainties and disruptions. ↩

Learn how anti-dumping duties can affect your product pricing and profitability in the European market. ↩

Explore strategies to build a resilient supply chain amidst global uncertainties. ↩

Understanding Section 301 duties can help you plan your sourcing strategy to avoid unexpected costs. ↩

Understand why China's technical expertise is crucial for complex ceramic projects. ↩

Learn how China's mature supply chain can speed up development and production processes. ↩

Discover how a 0% anti-dumping duty can make Thailand an attractive option for ceramic production. ↩

Stay informed about the tariff situation with China to make strategic sourcing decisions. ↩

Learn how having operations in multiple countries can protect your supply chain from disruptions. ↩

Explore how a trading-led model can simplify coordination and logistics across multiple factories. ↩

Learn how flexible MOQs can benefit brands looking to test new products with smaller runs. ↩